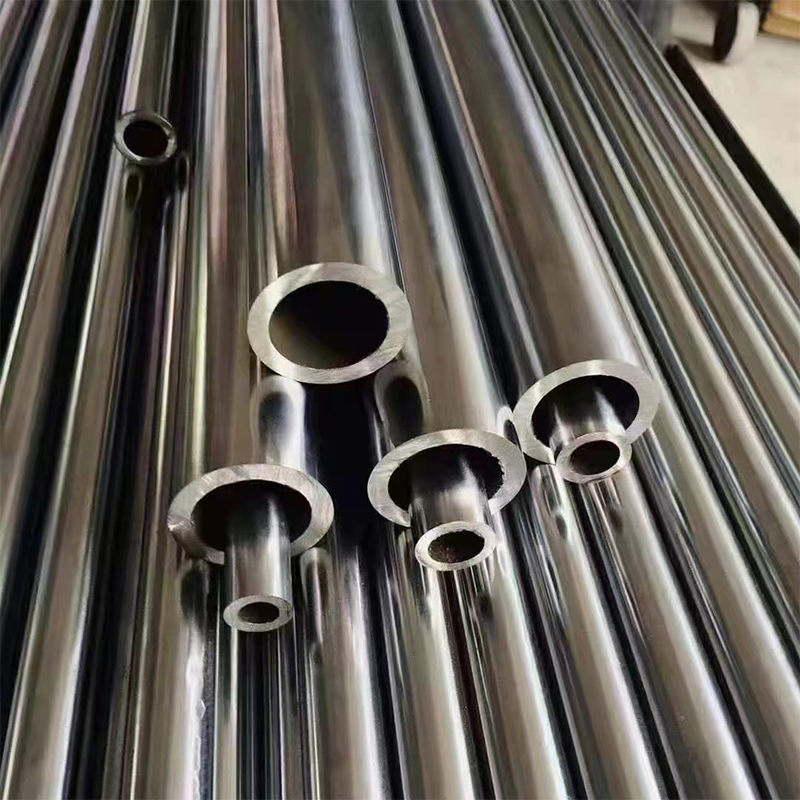

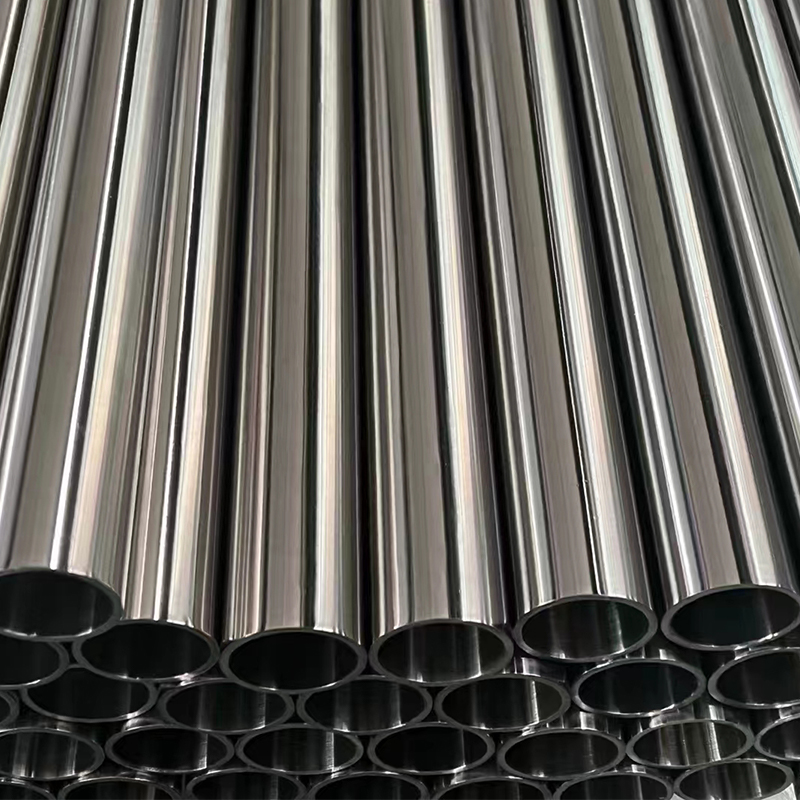

These days, stainless steel pipes now are considered to be indispensable in our modern world as they serve as durable and corrosion-resistant pathways required for a variety of industries. The oil, gas, boiler manufacturing and architectural industries are the main users of these tubes today - undoubtedly a versatile type of pipe! Being the rudimentary section of our infrastructure, stainless steel pipes are not only secure for their rust resistant features but remain presentable throughout years.

6 Reasons Why Stainless Steel Stand Head and Shoulders Above Other MaterialsCorrosion-Resistant One of the greatest attributes that set stainless steel apart from other materials is in its resistance to corrosion. If in contact with oxygen, it reacts to create a layer of protective chromium oxide (Cr2O3) on the surface of these pipes. This thin layer protects corrosion of the metal beneath, which renders it an indispensable element among applications where exposure to harsh environments is anticipated such as seawater or acid solutions. Specialized grades such as 304 or grade 316 stainless steel include nickel and molybdenum to protect the metal from certain types of corrosion.

Stainless steel pipes have become increasingly popular among a variety of end users not only because they are corrosion resistant. These pipes are widely used in high-pressure piping applications as their superior strength-to-weight ratio ensure long-term durability and safety. The sturdier nature also allows it to be heat-proof, thus aiding in having tolerance from very high temperatures. In addition, because stainless pipes are low maintenance and can last for decades before they need a replacement or repair no sooner translates to more savings. The fact that stainless steel possesses a non-porous surface, which is resistant to the growth of bacteria leading it to be highly used in industries such as food and pharmaceuticals for its hygienic properties making cleaning much more manageable.

Stainless steel pipes: As this is the time to be aware of sustainability, stainless pipes turn out as an eco-friendly option. Materials that are fully recyclable without any loss in quality fit perfectly within the principles of a circular economy. In addition, the stainless steel pipes are recyclable helping in reducing waste and resource allocation. Production of stainless steel is energy-efficient, which leads to reduced carbon footprints thereby in line with global sustainability objectives.

Stainless steel pipes are widely used across the diverse applications ranging from small businesses to others. Those pipes are used throughout construction to add a combination elegance and wear resistance, from shiny facades to chrome-plated handrails. It is the unquestionable standard for stainless steel pipe in industries such as petrochemical, where it conveys corrosive chemicals and high-pressure gases. It is used in water supply system to deliver the clean, fouling-free water. Stainless steel is widely used in the food and beverage industry because of its process piping, which needs to comply with ultra-strict hygiene standards. In the world of art and design, as well we can see artistic uses for stainless steel pipes.

We ss steel pipe and a highly professional approach to delivery for every order. Every detail is important to us, and we make sure that our customers are aware of it. The foundation of long-term relationships is accountability.

The company has an ss steel pipe and a highly skilled team that handles the customer's orders in a timely time and ensure timely delivery. The delivery process is based on the product's type and quantity, and the needs of the client.

Raw materials are procured from China's steels producers, such as Taiyuan Iron and Steel Group and Baosteel. We oversees the quality of our products to ss steel pipe and customers demands.

Core team members ss steel pipe of the industry that spans from customer service procedures to professional skills and from the market to business.

Several factors come into play when making a decision on choosing the right stainless steel pipe. Which stainless steel grade, based on the corrosion resistance and strength/ temperature required in application? This decision-making process is driven by environmental conditions, exposure to chemicals, salt and high temperatures. Furthermore, pipeline sizes should match to the system pressure and flow requirements while considering wall thickness for maximum performance. The fabrication issues including the welding processes and ease of fabricability against the life cycle cost of abovementioned pipe materials in one hand, on proven performance side such as joining integrity after years must also be analyzed. Following are the standard checks which we have to assure before delivering anything in production:-Throughout transportation,Production for avoiding any kind of discrepancy by providing a safe and performance oriented environment.

In summary, stainless steel pipes are the perfect marriage of form and function because they never rust, have a long service life while serving multiple applications in various sectors including architecture. Now the fact that these lines are only becoming more and more a part of our infrastructure, we need to be able to have an understanding on how unique and important they can alternatively become in order for us as human beings based parallelize with stuff like Planets future saving.